Крупногабаритные коробки: глобальный тренд в упаковке.

Мировая упаковочная индустрия переживает трансформацию. В связи с быстрым ростом электронной коммерции, мирового экспорта и, особенно, продаж бытовой техники и электроники, производители сталкиваются с новой задачей: как безопасно, эффективно и экологично упаковывать крупногабаритные и тяжелые товары.

Будь то 75-дюймовый телевизор, стиральная машина или кондиционер — для защиты этих громоздких предметов во время транспортировки необходимы прочные, негабаритные коробки из гофрированного картона. В результате спрос на крупноформатную упаковку растет быстрее, чем когда-либо.

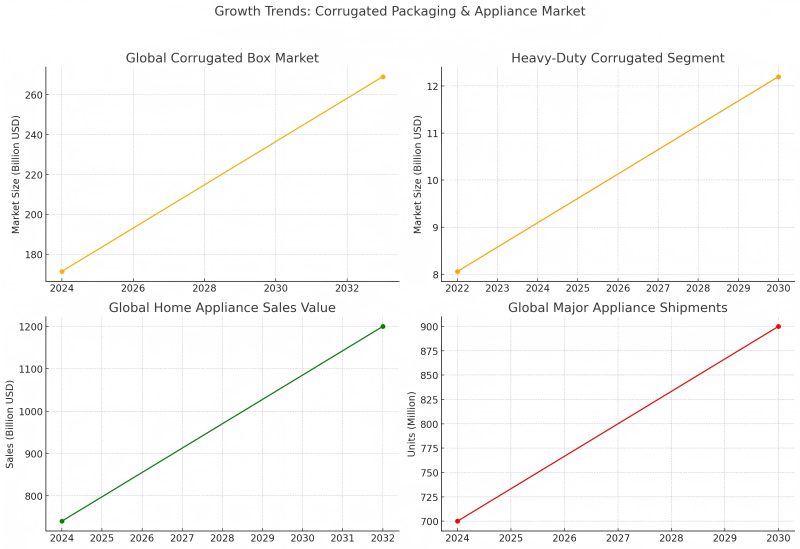

Анализ рынка

• Прогнозируется, что мировой рынок гофрокартонных коробок вырастет со 171,4 млрд долларов США в 2024 году до 269 млрд долларов США к 2033 году.

• Ожидается, что к 2030 году объем рынка только высокопрочного гофрированного картона достигнет 12,2 млрд долларов.

• Ожидается, что к 2032 году объем мировых продаж бытовой техники превысит 1,2 триллиона долларов США.

• К 2030 году во всем мире будет отгружено около 900 миллионов единиц крупной бытовой техники.

• Электронная коммерция стимулирует рост спроса на доставку крупногабаритных и хрупких товаров напрямую потребителям.

Для таких крупногабаритных товаров нужны большие коробки — прочные, штабелируемые и часто изготовленные на заказ. Гофрированные коробки отвечают этим требованиям: они прочные, пригодны для вторичной переработки и легче традиционных деревянных ящиков. Их популярность также обусловлена ужесточением требований к устойчивому развитию и ростом глобальной логистической активности.

Однако по мере роста спроса производители упаковки сталкиваются с новыми проблемами: быстрое и экономичное производство более крупных и сложных коробок без ущерба для точности и качества. Традиционные машины для складывания и склеивания не всегда справляются с этой задачей.

Технологии упаковки завтрашнего дня — уже сегодня!

Складная машина T-Fold Pro от DGM создана специально для решения этой задачи. Разработанная для высокоскоростного и высокоточного производства крупногабаритных гофрированных коробок, она объединяет передовую автоматизацию, эффективность использования материалов и исключительную универсальность в одной интеллектуальной машине.

В основе T-Fold Pro лежит система двойной подачи, позволяющая обрабатывать две заготовки из гофрированного картона одновременно. Они точно выравниваются и соединяются, образуя единую, сверхбольшую коробку — без необходимости ручного вмешательства или дополнительных этапов сборки. Процесс непрерывный, надежный и идеально подходит для крупносерийного производства.

Одно из главных нововведений заключается в методе двойной склейки «слева-справа», который заменяет традиционные перекрывающиеся клапаны соединением «край к краю». Это не только экономит материал картона, но и уменьшает габариты станка. Это элегантное решение, которое улучшает как рабочий процесс, так и экономическую эффективность, особенно для компаний, производящих большие коробки на ограниченной площади.

Система полностью сервоприводная, с регистрацией в реальном времени, автоматической центровкой и интуитивно понятным сенсорным интерфейсом. Операторы могут быстро устанавливать, регулировать и вызывать параметры задания, минимизируя время простоя и повышая производительность. Несмотря на свою техническую сложность, машина удобна в использовании, стабильна и надежна — даже при работе с толстым и тяжелым гофрированным картоном.

Помимо крупногабаритных коробок RSC, T-Fold Pro предназначен для работы со сложными типами упаковки, включая коробки TwinBox, коробки с запирающимся дном и винные коробки с перегородками. Он поддерживает интеграцию с системами MegaFold или Colt от DGM для создания полноценной поточной линии упаковки — от подачи и склеивания до связывания — в рамках единого бесшовного процесса.

Основные преимущества T-Fold Pro:

• Система двойной подачи: одновременно обрабатывает две заготовки для производства коробок нестандартных размеров.

• Соединение слева направо: соединение «край к краю» уменьшает расход материала и длину станка.

• Высокоскоростная автоматизация: система с сервоприводом и удобным интерфейсом обеспечивает точность и эффективность.

• Возможность работы с различными форматами: поддерживает двойные коробки, перегородки, замки на дне и многое другое.

• Масштабируемая интеграция: работает в автономном режиме или в паре с MegaFold и Colt для полной автоматизации.

В результате получается система, которая не просто производит коробки — она оптимизирует весь производственный цикл. Сокращая ручной труд, экономя материалы и повышая скорость и точность, T-Fold Pro позволяет производителям упаковки реагировать на растущий рыночный спрос без ущерба для прибыльности или точности.

Независимо от того, производите ли вы продукцию на мировой экспорт, для оптовой розничной торговли или для логистики тяжелых грузов, T-Fold Pro обеспечивает автоматизацию, надежность и производительность, необходимые вашим операциям — сегодня и в будущем.

Хотите модернизировать свою линию по производству крупноформатной упаковки?

Свяжитесь с нами сегодня, чтобы получить дополнительную информацию и посмотреть демонстрацию в режиме реального времени.

Дата публикации: 18 апреля 2025 г.