Application Scope and Production Requirements

In corrugated packaging production, large-format and heavy-duty cartons often involve double-piece structures, irregular box styles, and high strength requirements.These applications place higher demands on feeding stability, alignment accuracy, and forming consistency, especially when handling wide blanks and complex box designs.The DGM Tfold Pro Stitcher is developed to support such production scenarios, providing an integrated solution for double-piece gluing and double-piece stitching in large-format corrugated carton manufacturing.

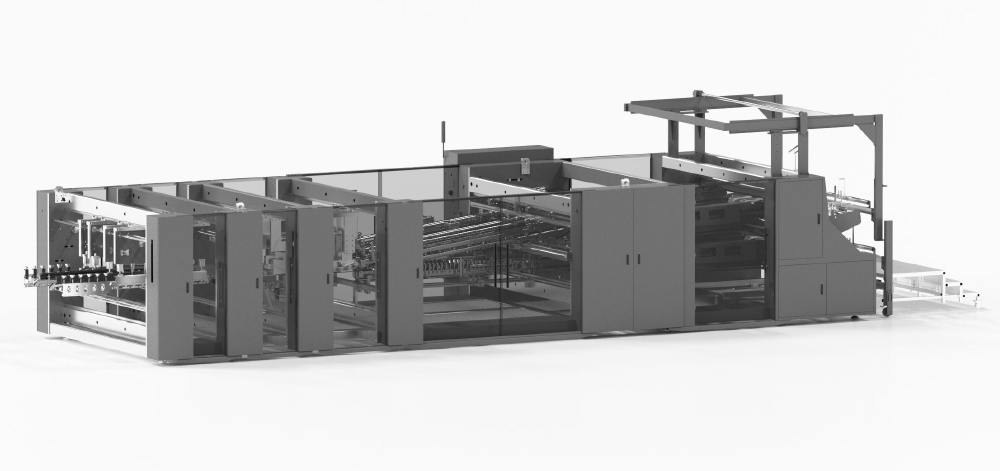

Machine Configuration and Core Design

The Tfold Pro Stitcher is available in 1650, 2000, 2400, and 3000 mm models, with a maximum mechanical speed of up to 150 m/min, and is specifically designed for large-size and heavy-duty corrugated board.One of the core design features of the Tfold Pro Stitcher is its double feeder structure.

For example, with a 2000 mm machine width, the Tfold Pro Stitcher is capable of producing corrugated boxes with a maximum blank width of up to 4000 mm.

This design meets the processing requirements of large-format corrugated boxes while reducing reliance on extra-wide machines, helping to optimize floor space utilization and lower overall equipment configuration and production line layout costs.

Key Technical Features

• Double feeder system with drawing file and memory functions, enabling fast order changeovers of approximately 10 minutes, supporting efficient multi-order production.

• 12 sets of imported vacuum suction valves, adjustable according to box style and blank length, ensuring smooth feeding without surface scratching and minimizing reliance on friction-based feeding.

• Upgraded linear guide rail machine frame, requiring high-precision machining and assembly, providing strong structural stability, high accuracy, small clearances, and simplified maintenance, even for wide machine frames.

• Capability to produce various double-piece corrugated box styles, including straight-line, irregular, and front-back offset structures.

• Gluing tolerance up to ±1 mm, supporting consistent box forming accuracy.

• Flexible and intuitive operating interface, allowing precise control of production parameters.

• Newly added mechanical side pull guide and servo-controlled front guide, improving adjustment convenience and alignment accuracy.

• The entire machine, including the conveyor section, is driven by 28 sets of servo motors, supporting synchronized and stable motion control.

• An optimized forming and joining section, suitable for diversified heavy-duty corrugated carton designs.

• Direct servo motor drive transmission, enabling high-precision control during box alignment, joining, and forming processes.

• Integrated support for both double-piece gluing and double-piece stitching, providing flexible process selection according to carton structure and strength requirements.

Production Value and Application Benefits

Through its structural design and servo-controlled system architecture, the DGM Tfold Pro Stitcher supports stable processing of large-format corrugated cartons while maintaining accuracy and operational flexibility.

The machine configuration is designed to help packaging manufacturers improve space efficiency, simplify production layouts, and adapt to diversified carton structures without relying on oversized equipment.

To learn more about the DGM Tfold Pro Stitcher and watch the full YouTube horizontal video, please click:

Post time: Jan-19-2026