The global packaging industry is undergoing a dynamic transformation, driven by rapid changes in consumer behavior, sustainability imperatives, and the relentless growth of e-commerce. As companies race to meet the complex demands of logistics, heavy-duty transportation, and sustainable practices, large-format corrugated packaging has emerged as a crucial solution. In 2024, the corrugated packaging market is valued at nearly $311 billion and is projected to reach $477 billion by 2034, growing at an estimated annual rate of 4 to 5%. Within this expansive market, the heavy-duty segment—catering specifically to bulky, high-weight products—is gaining exceptional momentum, expected to grow from $24 billion to $44.5 billion over the same period.

Several factors fuel this growth. E-commerce has revolutionized the packaging landscape, necessitating durable, protective solutions that can endure the rigors of global supply chains. Sustainability regulations are also prompting industries to shift away from plastic and other non-recyclable materials toward corrugated fiberboard, renowned for its recyclability and environmental compatibility. Moreover, sectors such as electronics, automotive, food, and home appliances increasingly require packaging that combines strength with logistical efficiency. This market landscape underscores a pressing need for innovation in packaging machinery—solutions that enhance productivity, guarantee structural integrity, and meet environmental standards.

DGM Technology has strategically responded to these demands with the MEGAFOLD PRO, an advanced folder gluer that integrates folding, gluing, and stitching within a single, cohesive system. This machine represents a significant leap forward for manufacturers of large-format corrugated packaging, offering a level of robustness, precision, and operational flexibility that aligns perfectly with modern production requirements. The MEGAFOLD PRO is specifically engineered to process up to 5-ply corrugated boards, accommodating various flute types including E, B, C, N, F, AB, and BC, and can handle blank widths up to 3200 mm. Its heavy-duty construction makes it ideal for producing boxes capable of withstanding high-stress conditions, which are often encountered in industrial and e-commerce logistics.

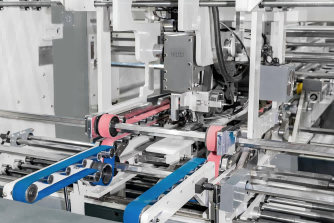

What truly sets the MEGAFOLD PRO apart is its seamless integration of gluing and stitching, eliminating the need for separate processing stages. The gluing function operates at speeds of up to 150 meters per minute, while the stitching process achieves between 20 to 80 meters per minute. At the heart of its stitching capability is an independent servo motor-driven station, equipped with a high-precision stitcher and a sophisticated squaring device that ensures perfect alignment of every box before stitching. This precision is crucial for maintaining structural integrity, especially for large and heavy packaging, with a join gap accuracy of ±2 mm and operational availability exceeding 98%.

Designed with the operator in mind, the MEGAFOLD PRO features motorized carrier movements on high-precision linear guides, automatic setup functions, and memory capabilities that significantly reduce changeover times. The machine's collapsible carriers allow easy access for maintenance, while its extensive 8-meter folding and closing section ensures smooth material flow even at high speeds. A total of 13 sets of 90mm width suction feeding belts, complemented by a front-edge feeder and pneumatically adjustable side plates, guarantee consistent and reliable feeding of materials.

Complementing these core functionalities, the MEGAFOLD PRO includes a dust elimination module for maintaining a clean production environment and a dedicated stacking station with an integrated buffer. It also features rapid connection interfaces for downstream equipment like strapping and bundling systems, ensuring seamless integration within complex production lines.

The MEGAFOLD PRO's industrial-grade credentials are evident in its imposing specifications: 28.8 meters in length, 23 tons in weight, and an operating pressure of 6 bar compressed air. These features underscore its capacity to handle the most demanding production scenarios, especially where durability, consistency, and efficiency are non-negotiable.

Beyond its mechanical prowess, the MEGAFOLD PRO addresses the industry's growing emphasis on sustainability and operational cleanliness. Optional modules, such as plasma treatment systems, enhance adhesive performance on laminated or UV-coated surfaces, further broadening the machine's applicability while minimizing waste.

In an industry where time, reliability, and adaptability define competitiveness, the MEGAFOLD PRO is more than a machine—it is a strategic asset. It enables manufacturers to consolidate processes, reduce labor costs, and elevate production capabilities, all while meeting the evolving standards of quality and sustainability. As the packaging sector continues to expand and diversify, investing in integrated, high-performance solutions like the MEGAFOLD PRO is essential for businesses aiming to stay ahead in a challenging global market.

With DGM's commitment to innovation and excellence, the MEGAFOLD PRO stands as a comprehensive breakthrough in stitching and gluing integration—where power, precision, and efficiency converge to redefine the future of packaging.

Post time: Jul-23-2025