A Market in Expansion and Transformation

The global corrugated packaging industry continues to grow steadily, driven by sustainability goals, e-commerce logistics, and the need for larger and more durable boxes. According to recent reports from Smithers and MarketsandMarkets, the sector is projected to exceed USD 205 billion by 2030, growing at an average annual rate of 3%–4%.

Major growth is concentrated in the food delivery, furniture, beverages, and e-commerce sectors, where large-format packaging is essential for logistics and protection.

At the same time, manufacturers face new challenges: shorter delivery times, skilled labor shortages, and increasing demand for precision and repeatability. As a result, converters worldwide are investing in automation and inline integration — reducing manual operations and optimizing every stage of the converting process. Servo-driven equip

An Integrated Solution for Corrugated Excellence

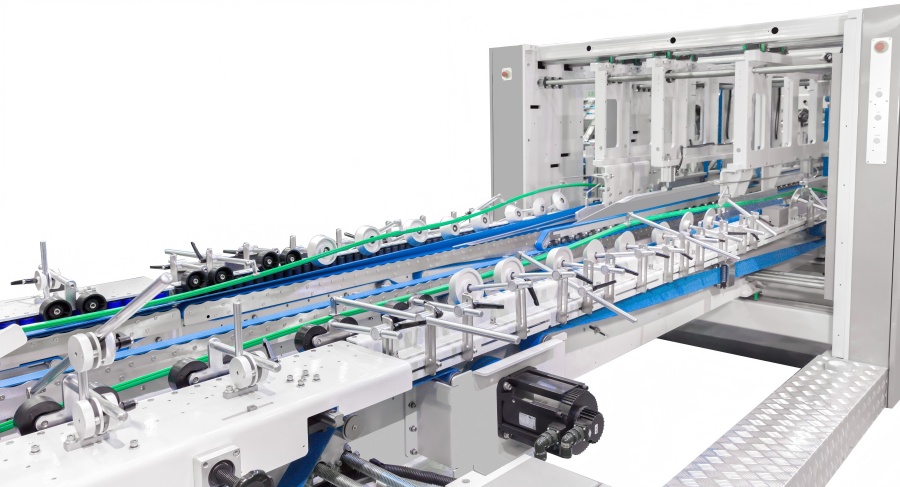

DGM Technology, a global manufacturer with more than 25 years of experience in carton converting machinery, has developed one of the most advanced inline solutions for corrugated packaging: the TFold Pro + Megafold + Colt line.

This configuration integrates every stage of the process — from feeding and gluing to folding, counting, turning, and strapping — into one synchronized production flow.

- TFold Pro – Double-Feeder Precision

The TFold Pro introduces two independent feeders (upper and lower), each powered by a dedicated servomotor. This system allows simultaneous feeding and gluing of two-piece cartons such as TwinBox, TwinPack, or large-format beverage and industrial boxes.

• Servo synchronization ensures ±1 mm alignment accuracy.

• Dual Hot-Melt and cold-glue systems deliver perfect bonding even on thick corrugated materials up to 8 mm.

• With a working width of 2000 mm and compatibility with corrugated grades A, B, C, E, K, BC, EB, AB, and 3–5 plies, TFold Pro provides unmatched versatility and reliability.

- Megafold – Heavy-Duty Folding and Gluing

After the TFold Pro, the glued blanks move seamlessly into the Megafold folder gluer, a robust solution for medium to large boxes, capable of reaching 300 m/min.

• Each section — pre-folding, bottom lock, crash-lock, or 4/6-corner — operates through independent servo control, ensuring precise and smooth folding.

• Motorized carriers and job memory simplify setup and minimize downtime.

• A 7.5-meter press section provides powerful and even pressure, ensuring perfectly squared and bonded boxes.

- Colt – Intelligent Counting, Turning, and Strapping

Completing the line, the Colt automatic packer transforms finished boxes into perfectly organized bundles.

• It counts, stacks, flips every second bundle 180 degrees, and straps automatically in one continuous motion.

• This ensures precise, stable, and uniform bundles ready for shipping.

• The result is higher productivity with fewer operators and consistent quality every time.

Why This Line Matters

The TFold Pro + Megafold + Colt combination is a response to the most pressing needs of today’s corrugated industry:

• Full Inline Automation: A complete line managed by a single operator.

• Higher Productivity: Continuous feeding and servo synchronization maximize efficiency.

• Perfect Accuracy: Servo control guarantees precision in alignment and folding.

• Consistency and Safety: Automated counting and strapping eliminate human error.

• Adaptability: Handles a wide range of box types, from oversized shipping cartons to complex multi-piece designs.

Trends and the Road Ahead

The next decade will be defined by automation, sustainability, and traceability. Corrugated packaging continues to gain ground thanks to its recyclability and strength, but competition now depends on who can produce faster, smarter, and more efficiently.

Inline production systems like the TFold Pro + Megafold + Colt embody the future of converting — merging speed, intelligence, and flexibility in a single flow.

By reducing waste, setup time, and labor dependency, this configuration empowers converters to meet the growing demand for large-format, high-quality corrugated packaging.

Conclusion

The TFold Pro working inline with Megafold and Colt is not merely a machine combination — it is a complete, synchronized production ecosystem.

It represents DGM’s commitment to efficiency, precision, and innovation in corrugated packaging.

In a market where automation and quality define competitiveness, this integrated solution stands as a benchmark for productivity and reliability — delivering boxes that are not only perfectly folded, but also perfectly packed and ready to ship.

Post time: Oct-10-2025