TECHNOFOIL 1050-FLC Automatic Platen Hot Foil Stamper & Die Cutting Machine. It can run large format die-cutting and stamping with longitudinal, transversal foil pull system and Holo-gram. High precision, high speed, easy to operate, quick changeovers, durability and stable performance. Features that make this machine one of the best options available.

Automatic feeder with non-stop system, with pallet and cart direct load.

4 lift-up and 4 delivery suckers, designed to handle a wide range of materials from pa-per to corrugated board, guarantee the accuracy, reliability and smoothness of paper feeding.

Double sheet detector.

Quick changeovers, easy to operate.

2 register side guides working with pulling and pushing system.

4 register front lays, independently adjustable.

Closed chase with central positioning system device for fast positioning of the die.

Cutting plate 5 mm thickness.

Pressure control system, can be easily adjusted through touch screen. It has a securi-ty system to avoid any damage in the press.

Manual and automatic lubrication system.

7 light weight gripper bars.

Turn-over bracket for cutting chase and honeycomb chase.

Pneumatic lock and release system for cutting chase and honeycomb plate.

Heating system in 12 temperature zones with individual temperature control.

Foil break detector.

Films fasten device.

Foil unwind device.

Honeycomb chase.

High precision servo motor control system.

Holographic foil sensor tracker.

Foil tensioning system.

Optical fiber precise positioning system, together with hologram foil unwind and foil fasten devices, make sure accurate registration and stamping.

Non-stop device with automatic conveyor at delivery.

4 foil rolls in a high precision longitudinal foil feeding system.

Air blast foil separation system.

Foil tensioning system.

2 foil rolls in a high precision transversal foil feeding system.

Paper

Carton Board

Corrugated Board

Processed Materials

Paper from 80 g/m²

Carton board max. 2000 g/m²

Corrugated board max. 4 mm

Capability

Sheet size min. 350 x 400 mm

Sheet size max. 740 x 1050 mm

Speed max. 7500 s/h

Stamping speed max. 6000 s/h

Cutting force 4 00 Ton

Converting

Stamping & embossing size max. 720 x 1020 mm (Longitudinal and Hologram)

Stamping & embossing size max. 580 x 1020 mm (Transversal)

Die cutting size max. 730 x 1040 mm

Heating System

Heating zones 12 units

Temperature max 200 ºC

Foil Equipment

Foil length 120 to 1200 m

Web width 50 to 1020 mm (Longitudinal)

Web width 50 to 630 mm (Transversal)

Web advance shafts 3 (Longitudinal)

Web advance shafts 2 (Transversal)

Pile Height

Feeder max. 1650 mm

Feeder with non-stop 1270 mm

Delivery max. 1300 mm

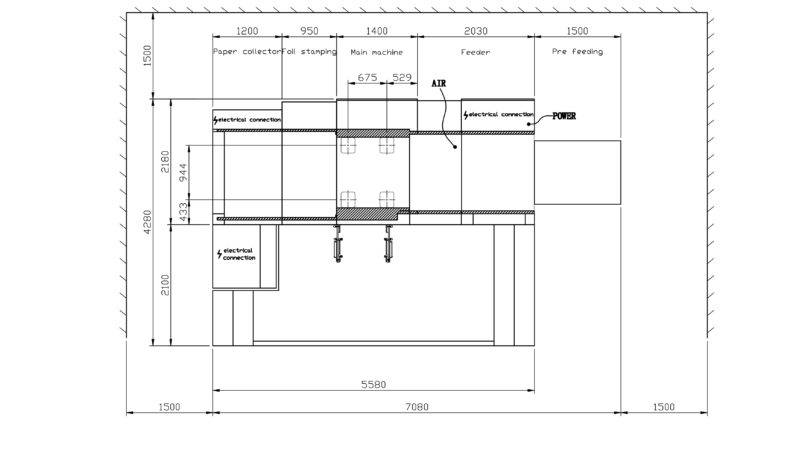

Dimensions & Weight

Length x Width x Height 7.08 x 4.28 x 3.26 m

Weight 21 Ton

Installation

Power supply 60 kW

Compressed air 6 bar

Air compressor capacity 30 m³/h

Air tank capacity 155 L