TECHNOFOLD 1450 – AC

Without pre-folding section.

Suitable for straight-line, crash-lock bottom & double wall boxes.

TECHNOFOLD 1450 – PC

Suitable for straight-line, crash-lock bottom & double wall boxes.

TECHNOFOLD 1450 – SL

Suitable for straight-line, crash-lock bottom, double wall, 4 & 6-corner boxes.

TECHNOFOLD-1450 Ideal for working with medium and large boxes in the heavy packaging industry. Its design includes driven upper carriers, making easy the precise folding and closing micro-flute and corrugated boxes in its advance.

The new Technofold series inherits the best features of the previous Technofold ES series, making a qualitative leap by developing new solutions. Versatility, fast exchange of accessories, easy setup together with faster production speed, guarantee a high productivity and quality of work. Technofold, the perfect folder-gluer machine for the most demanding packaging market.

Driven independently by servo motor.

Adjustable electronic pile vibrator.

Lateral feed gates fully adjustable to the width of the blank.

10 feeder belts.

Three adjustable front feed knives.

Independent section with an unparallel lower carrier that guides the box to a parallel handrail that allows a perfect blank alignment.

Left hand glue flap pre-folder up to 180º.

Third crease line pre-folder up to 135º.

1st and 3rd crease openers.

3 sets of upper and lower carriers.

Complete set of folding hooks and helixes to fold the front flaps of the blank smooth and accurately.

Set of accesories for “B” lock bottom.

Left lower gluing tank.

Easy to remove and clean.

Optional electronic upper gluing system by guns, upon request.

Smooth and accurate folding of 2nd and 4th creases.

Outer folding belts adjustable up to 180º with variable speed.

Three upper and lower carriers.

25 mm lower and 30 mm outer belts on left and right carriers.

Width-wise adjustable heavy duty compression rollers.

Upper and lower drive mechanism for length adjustment.

Equipped with automatic belt tension-adjusting system.

Continuous and automatic box collection mechanism that ensures a neat transfer to the Press section, guaranteeing a well aligned flow.

Electronic counter and ¨Kicker¨ for marking packets.

Independent & motorized press section.

Manual and Automatic mode (follow up).

Upper section moves back and forward, allowing for different box length.

7.4 meters total length with 4.0 meters effective pressure length.

Pneumatic pressure adjustment.

Suitable to fold rear 4 & 6-corner flaps or panels and many other designs.

Motorized and untimed electronic back folding system with intelligent servo motor technology.

Easy to setup through the main touch screen.

Paper

Carton Board

Corrugated Board

Processed Materials

Carton max. 1200 g/m²

Corrugated flute type N, E, F & B

Capability

Speed max. 300 m/min

Inching speed 20 m/min

Thickness of folded box max. 15 mm

Blank width max. 1450 mm

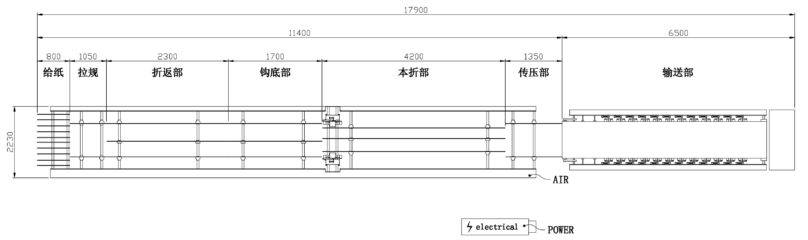

Dimensions & Weight

Length AC: 16.6 m PC: 18.9 m SL: 18.9 m

Width AC: 2.1 m PC: 2.1 m SL: 2.25 m

Height AC: 1.5 m PC: 1.5 m SL: 1.5 m

Weight AC: 10 Ton PC: 10.8 Ton SL: 11.4 Ton

Installation

Electrical connected load AC: 26 kW PC: 26 kW SL: 26 kW

Compressed air 6 bar

Air compressor capacity 10 m³/h

Tank capacity 60 L

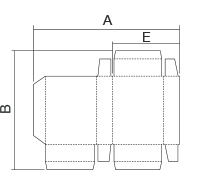

A: 220 - 1450 mm

B: 150 - 900 mm

E: 100 - 710 mm

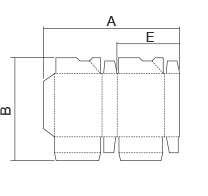

A: 220 - 1450 mm

B: 150 - 900 mm

E: 100 - 710 mm

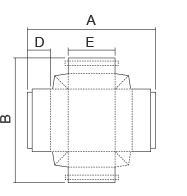

A: 320 - 1450 mm

B: 100 - 800 mm

D: 30 - 150 mm

E: 100 - 1300 mm

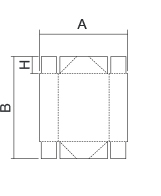

A: 280 - 1450 mm

B: 180 - 800 mm

H: 25 - 150 mm

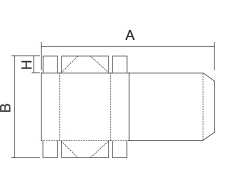

A: 430 - 1300 mm

B: 180 - 800 mm

H: 25 - 150 mm

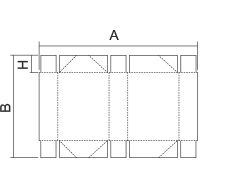

A: 430 - 1450 mm

B: 180 - 800 mm

H: 25 - 150 mm