صنعت بستهبندی در حال گذر از یکی از پویاترین تحولات خود در دهههای اخیر است. بستهبندی که زمانی صرفاً یک جزء محافظتی بود، اکنون یک دارایی استراتژیک برند است - اولین نقطه تماس بین یک محصول و مصرفکننده آن، و سفیر خاموش کیفیت، ارزش و پایداری. در بخشهای ممتاز مانند لوازم آرایشی، نوشیدنیهای الکلی، شیرینیهای لوکس و لوازم الکترونیکی، ظاهر و حس بستهبندی میتواند به اندازه خود محصول مهم باشد. تکنیکهای تکمیلی مانند برجستهکاری، برجستهکاری و برشهای پیچیده قالبی از جلوههای طراحی گاهبهگاه به الزامات استاندارد برند تبدیل شدهاند.

با این حال، ارائه این محصولات سطح بالا با سرعتی که بازارهای امروزی تقاضا میکنند، یک چالش است. چرخه عمر کوتاهتر محصولات، نسخههای فصلی و تغییرات سریع طراحی، تولیدکنندگان را مجبور میکند تا در زمان کمتری، تنوع بیشتری تولید کنند. در عین حال، افزایش هزینههای نیروی کار، کمبود اپراتورهای ماهر و فشار مداوم برای کاهش ضایعات، اولویتهای سرمایهگذاری را تغییر میدهد. دیگر کافی نیست که ماشینهایی داشته باشیم که صرفاً سریع باشند؛ آنها باید انعطافپذیر، یکپارچه و قادر به ترکیب فرآیندهایی باشند که قبلاً به چندین بار عبور نیاز داشتند. پایداری نیز یک محرک کلیدی است - تعداد دفعات کمتر به معنای مصرف انرژی کمتر، ضایعات کمتر و خطاهای کمتر در جابجایی است که تولید را با انتظارات نظارتی و مشتری هماهنگ میکند.

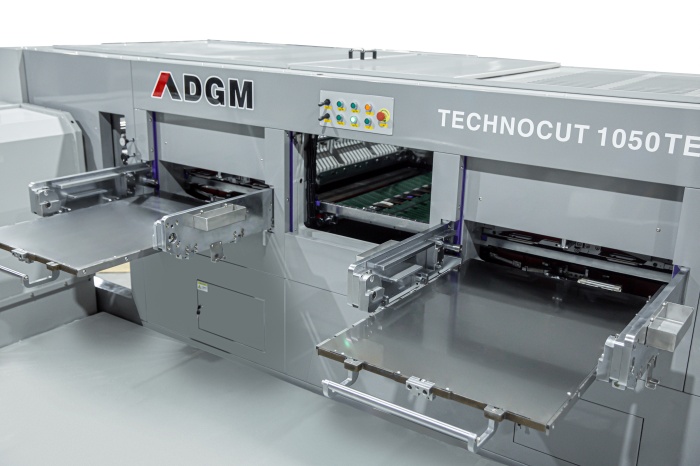

در این محیط طاقتفرسا است که DGM معرفی میکندتکنوکات TE، یک دستگاه برش قالب دو ایستگاهه با راندمان بالا که برش قالب و برجستهسازی عمیق را در یک چرخه تولید واحد ادغام میکند. به طور سنتی، این دو فرآیند به پاسهای جداگانه نیاز دارند: ابتدا ورق به شکل مورد نظر برش داده میشود و سپس برای برجستهسازی به دستگاه دوم تغذیه میشود. این نه تنها به معنای زمان بیشتر، بلکه به معنای جابجایی بیشتر، تنظیمات بیشتر و فرصتهای بیشتر برای عدم ترازبندی نیز بود. با گرد هم آوردن هر دو عملیات در یک گردش کار هماهنگ، Technocut TE به طور قابل توجهی زمان تولید را کاهش میدهد، جابجاییهای میانی را حذف میکند و ثبت کامل بین برش و برجستهسازی را تضمین میکند.

طراحی این دستگاه بر اساس دو پرس است که به طور هماهنگ کار میکنند - اولی به برش دقیق قالب و دومی به برجستهسازی عمیق اختصاص دارد. این پیکربندی به ویژه برای بستهبندیهای لوکس ارزشمند است، جایی که حتی کسری از یک میلیمتر انحراف در ترازبندی میتواند تصویر یک برند را به خطر بیندازد. سیستم پیشرفته تنظیم میکرو DGM به اپراتورها اجازه میدهد تا قالبها را با دقت مطلق تنظیم کنند و تضمین کنند که ساختارهای پیچیده و برجستهسازی حساس به برند از اولین ورق تا آخرین ورق بیعیب و نقص باقی میمانند.

کارایی در دنیای بستهبندی امروز به معنای سازگاری نیز هست و در اینجا Technocut TE میدرخشد. سیستمهای تعویض سریع برای قالب و صفحات برجستهسازی، جابجایی بین کارها را سریع و آسان میکند. تبدیلکنندگان میتوانند در همان شیفت کاری، بدون کاهش توان عملیاتی، از یک سفارش کارتن تاشو در مقیاس بزرگ به یک قطعه تبلیغاتی کوتاهمدت تغییر دهند. این توانایی واکنش سریع به تغییرات بازار و خواستههای مشتری میتواند تفاوت بین برنده شدن یا باختن کسبوکار در یک چشمانداز رقابتی باشد.

فراتر از قابلیتهای اصلی برش و برجستهسازی، Technocut TE میتواند به سیستمهای اختیاری جمعآوری ضایعات و انباشت پرزهای زیاد مجهز شود. این سیستمها دو مرحله از پرزهای پر زحمت پس از چاپ را خودکار میکنند، یعنی حذف ضایعات در خط و تحویل پرزهای کاملاً چیده شده آماده برای مرحله تولید یا ارسال بعدی. این امر نه تنها بهرهوری را افزایش میدهد، بلکه با کاهش بلند کردن و جابجایی دستی، ایمنی محل کار را نیز بهبود میبخشد.

این دستگاه برای طیف وسیعی از کاربردها طراحی شده است - از کارتنهای تاشو برای کالاهای مصرفی و دارویی گرفته تا قطعات جعبههای سخت برجسته برای برندهای لوکس و کارهای پیچیده چند فرآیندی که قبلاً به چندین دستگاه نیاز داشتند. در تمام این موارد، Technocut TE کیفیت بالایی را که این بخشها به آن نیاز دارند، ارائه میدهد، اما با سرعت و کارایی که برنامههای تولید مدرن به آن نیاز دارند.

از بسیاری جهات، Technocut TE بازتابی از آینده تولید بستهبندی است: انجام کار بیشتر در زمان کمتر، با ضایعات کمتر، در عین حفظ - و حتی بهبود - استانداردهای کیفیت. برای تبدیلکنندگانی که با حجم سفارشهای رو به رشد، طرحهای پیچیدهتر و فشار بیوقفه برنامههای تحویل سریعتر مواجه هستند، این چیزی بیش از یک دستگاه است - این یک تحول در گردش کار است. این به کسبوکارها اجازه میدهد سریعتر پاسخ دهند، هزینهها را کاهش دهند، نمایه پایداری خود را افزایش دهند و اعتبار خود را برای دقت و قابلیت اطمینان تقویت کنند.

مزایای کلیدی در یک نگاه

• ادغام دو ایستگاه- برش قالبی و برجستهسازی عمیق در یک مرحله، که باعث کاهش زمان تولید و جابجایی میشود.

•سیستم میکرو تنظیم- هماهنگی کامل را برای طرحهای حیاتی برند تضمین میکند.

•ابزارآلات با قابلیت تعویض سریع- تعویض سریع برای حداکثر انعطافپذیری در کوتاهمدت و بلندمدت.

•ماژولهای اتوماسیون اختیاری- جمعآوری ضایعات به صورت درون خطی و انباشت در ارتفاع بالا برای کاهش نیاز به نیروی کار و بهبود ثبات.

•کاربردهای متنوع— از کارتنهای تاشو گرفته تا عناصر جعبههای سخت برجسته، همه با پرداختهای باکیفیت عالی.

با پشتیبانی شبکه پشتیبانی جهانی DGM، هر نصب Technocut TE با مشاوره تخصصی، آموزش کامل اپراتور و خدمات فنی پاسخگو همراه است. ترکیب فناوری پیشرفته و پشتیبانی قوی پس از فروش تضمین میکند که این دستگاه نه تنها نیازهای امروز را برآورده میکند، بلکه با تکامل نیازهای بازار، به عملکرد خود ادامه میدهد.

برای مبدلهایی که به دنبال تبدیل پیچیدهترین کارهای بستهبندی خود به کارآمدترین گردش کار هستند، Technocut TE پاسخی روشن و قدرتمند ارائه میدهد.

DGM - دقت. قدرت. عملکرد.

زمان ارسال: ۱۵ آگوست ۲۰۲۵